The plant allows the parallel production of up to 10 spread and impregnated fiber tapes. The spreading of fiber rovings uses the principles of rope friction: as a result, the individual filaments spread out and the original roving width increases significantly depending on the fiber type.

The plant technology focuses on the processing of 12K carbon rovings, which can be spread from 10 mm to more than 17 mm tape width using the technology employed. The spread tapes are then impregnated with a thermoplastic dispersion. The drying module is designed for temperatures of up to 450°C, enabling the processing of PEEK dispersions. The system speed is up to 10 m/min. The end product achieves a fiber volume fraction of 60% and a tape width of up to one inch when doubled, wound as a disc spool.

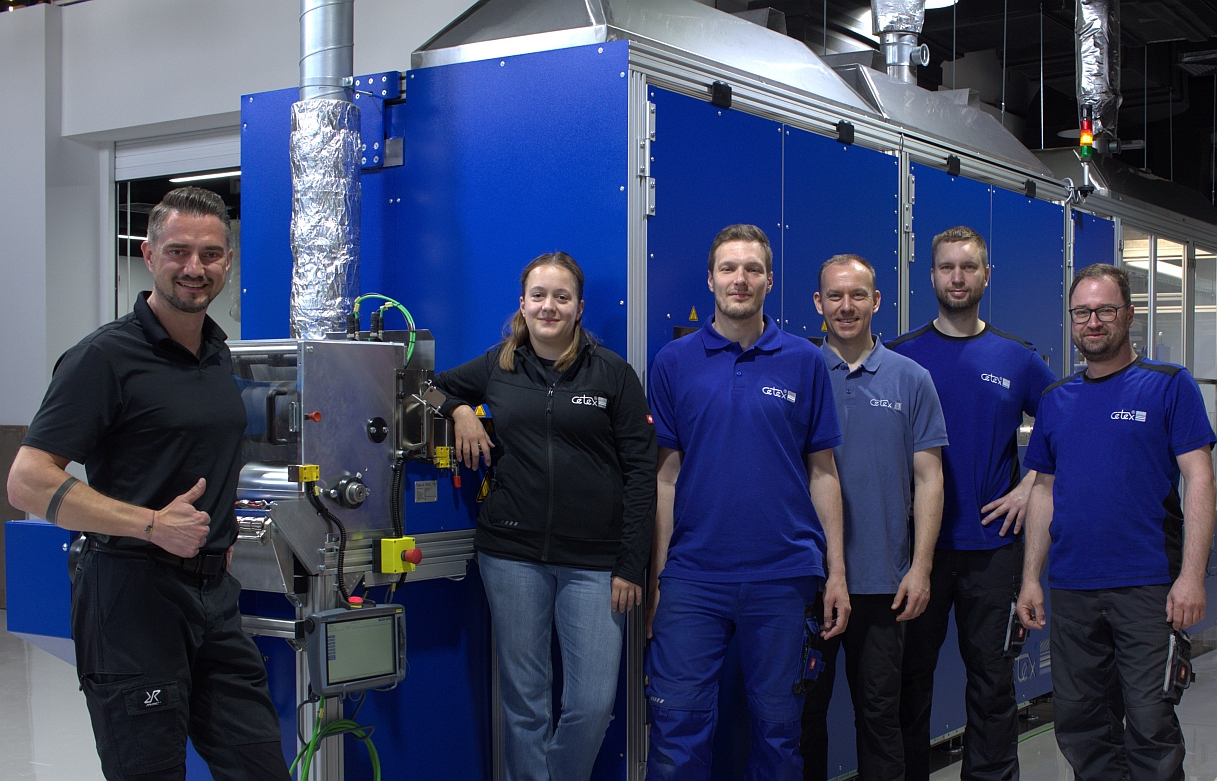

The successful commissioning marked the end of an exciting project, with the installation being just the beginning of a long-term cooperation.

Are you also interested in a similar coating system? Then get in touch with us and take advantage of the opportunity to test materials on a modular prototype system in our technical center.

contact person

Dipl.-Wi.-Ing. Sebastian Nendel

Managing Director

+49 (0)371 5277-200

Contact by mail