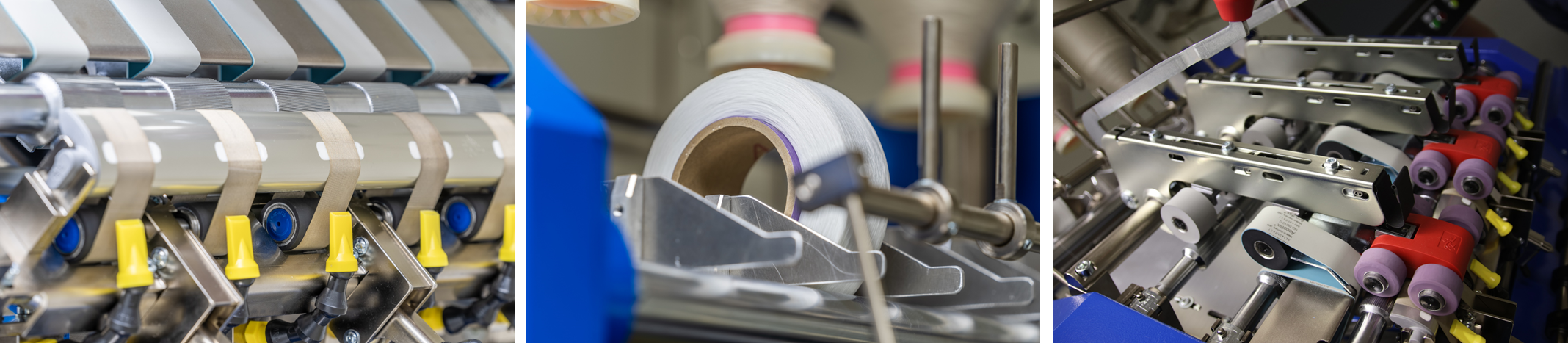

LSE 2000-2 | The compact and flexible Lab Spinner

All staple fibres made of cotton, wool and man-made fibres can be processed on our Lab Spinning Unit LSE 2000-2.

Three interchangeable drafting system types and a variety of additional modules guarantee optimum production results for core, compact, siro, S and Z as well as fancy yarns on a laboratory scale for your product development, research and teaching.

Flexible laboratory spinning unit for

- Yarn producers

- Producers of textile machines

- Producers of components

- Research facilities

- Educational institutions

Highlights of the LSE 2000-2 for maximum flexibility

- Compact, modular design (integrated control cabinet)

- Basic machine with 3 interchangeable drafting systems

- 3-roller short staple

- 4-roller short staple (for sliver spinning)

- 3-roller long staple

- Variable spinning geometry with adjustable drafting inclination

- Infinitely adjustable draftings

- Six individually driven spindles

- Clearly arranged large control panel

- Further integrable add-on modules for numerous yarn constructions

- Optional remote diagnosis

Downloads

contact person

Dipl.-Ing. Toralf Jenkner

Head of Research Department Classic Textile Machinery Development

+49 371 5277-282

Contact by mail